Bread Making & Baking Machines |

Bread Baking Oven

Construction

:

Ask for Price?

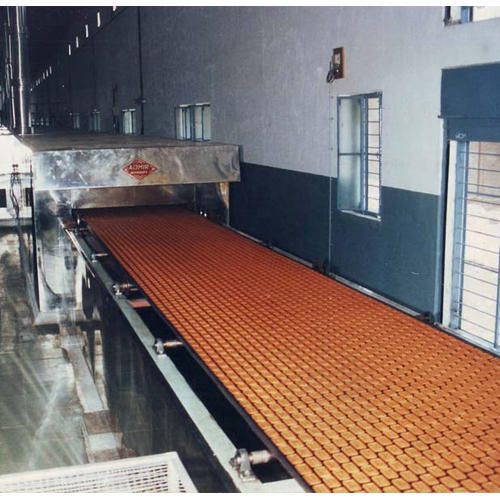

The

oven body consists of steel steamtight tunnel with equally divided zones of

the radiators. Stainless steel expansion joints are provided between these

zones in order to eliminate the expansion of the oven section. The

inspection doors are provided for inspection of the baking goods during the

process.

Firing Chambers:

The complete chamber will be insulated with minerwoll filled from outside

to conserve heat and increase efficiency. The fully automatic imported

burner shall be fitted to the chamber and the temperature shall be

controlled by automatic temperature controller on the control panel.

Insulation:

The complete oven will be covered with 10" thick mineral wool

insulation from top, bottom and the sides. The bottom portion of the oven at

the sides will be covered with CRC sheets for the conveyor protection and to

avoid heat loss.

Baking

System:

The baking in the heating chamber takes place by radiators located under

and above the wire mesh band which distribute heat for uniform baking. The

recirculation heating gases of these radiators can be controlled for each

zone separately. The closed recirculation system is having slight vacuum so

that combustion gases can not enter into the baking chamber. The ventilating

fan is for circulation of the heating gases through the recirculation system

and thermostatically controlled burners provide the set temperature of the

heating gases.

Fans:

All the circulating fans are fabricated from M.S. & S.S. and will be

well balanced to avoid vibration and will give noise free operation in high

speeds.

Capacity: 2000 breads per day of 400 gms loaves

Product Details:

| Machine Body Material | Steel |

| Capacity | 2000 breads/day |

| Type | Automatic |

| Design Type | Customized |

| Controlling Mode | Digital Time Control |

| Installation | Freestanding |

| Material | Stainless Steel |

| Application | Biscuit |

| Driven Type | Electric |

Ask for Price?

Firing

Chamber:

The complete Firing chamber will be insulated with mineral wool filled from

out side to conserve heat and increase efficiency. The firing chambers Shell

fabricated out of stainless steel. The Oven can maintain temperature up to

350° and temperature rises from room temperature to 225° in just

25 minutes.

Heat Circulation:

The hot air is distributed evenly into the Oven by a blower fan and oven's

rotary movements provide even & uniform baking at all levels of the

rack. Oven has an indirect diesel fired heating system so that burnt gases

do not come in contact with the baking products. The fully automatic

imported burner will be fitted to the chamber and the temperature controlled

by automatic temperature controller, fitted on the control panel.

Door:

A full stainless steel door provides with heat resistance silicone gasket

that sealed the door and gains heat of the oven.

Insulation:

The complete oven will be covered with mineral wool insulation and Mild

steel or Stainless steel covers to avoid heat loss.

Construction:

The oven body consists of mild steel. The structure of oven is stand on

angle frame and the all side of oven will be covered with Mild steel or

Stainless steel sheets.

Inspection:

The Stainless Steel doors are provided with Toughened glass and interior

light for the inspection during the process.

Rack:

The baking product is to be put in trays, which are placed in the rack,

which rotates at a low RPM through a system of gearbox and motor, located at

the top of the Oven

Electrical:

Three Phase Electricity (240V / 415) required running the system.

Electrical controls indicators and starters will be fitted on the control

panel.

Fan:

The circulating fan will be well balanced to avoid vibration and will give

noise free operation in high speeds.

Temperature Control:

A digital indicating controller maintains temperature in the Oven, which

comes with safety thermostat and a timer along with a hooter that helps in

baking cycle.

Product Details:

Having four speeds for mixing eggs & cream for cookies, pastry etc.

The machine is supplied with S.S bowl, one egg whisk & beater. all the above attachment are stainless steel.

The range of Diesel Traveling Bread Oven offered by us is made available in different operating specifications so as to perfectly match up with the specific operational demands of the customers. Made available in different sizes like medium or large, these are made from quality stainless steel so as to provide quality performance standards in give applications.

Product Details: